At TANAJET, one of the usual jobs performed is the disassembly and assembly of the tail shafts for the captain’s inspection, taking the opportunity to check that all the elements are in perfect condition.

Disassembly, overhaul and assembly of a shaft line:

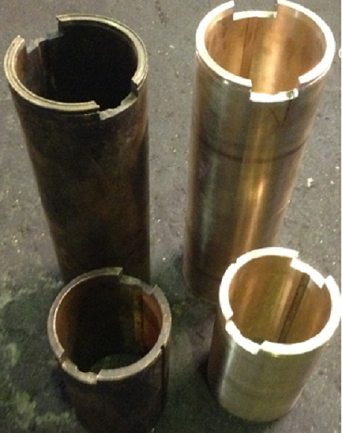

Move to the V de Bravado slipway for the disassembly of a line of shafts, starting with the disassembly of the rudder, propeller, shaft, shaft seals, friction bushings bow and stern to bring them to the workshop for review and calibration, find worn shaft and bushings, the propeller is removed from the shaft to take the shaft to be machined and also manufacture new bushings applying a new anti-friction component to have a better rotation. With all the material ready, the blade is mounted on the shaft in the workshop and taken to Bravado’s V slipway to begin assembly. The bushings and seals are mounted and then we proceed with the assembly of the shaft and propeller. With a pedal grease gun the horn is filled with grease to keep it greased so as not to see any leakage. Once the shaft is assembled, the shaft is aligned with the reduction gear. Subsequently the boat is voted to the water and navigation tests are made.